plastic wall thickness measurement|wall thickness chart : manufacturing Measuring the wall thickness of plastic bottles is critical to ensuring their structural integrity, product protection, material optimization, and overall quality. 22 de fev. de 2024 · Como saber se kabuumloja.com é confiável? Tome sua decisão de compra, acesso ou cadastro a partir do resultado da verificação que fizemos. Abaixo algumas dicas para você entender melhor os dados: Tempo de registro: prefira sempre empresas que já estejam no mercado há mais tempo, é comum que sites fraudulentos .

{plog:ftitle_list}

webForneça a melhor experiência do usuário para seus clientes, permitindo que eles paguem por jogos e itens no jogo com métodos de pagamento locais. Com o processamento local, você aumentará sua taxa de aprovação enquanto mantém uma taxa de estorno baixa. .

The DeFelsko PosiTector UTG P precision wall thickness gauge uses proven ultrasonic technology to quickly and accurately measure the wall thickness of plastic bottles and other relatively thin plastics and metals.

Plastic Product wall thickness is a critical structural feature frequently discussed and considered in the design of plastic product structures. It represents the thickness value between the outer and inner walls of a plastic part.

The most typical wall thickness is 1.8-3mm, which varies according to the kind and size of the plastic element. In order to get to know wall thickness easily, the specifications of commonly used wall thicknesses under various plastic . Measuring the wall thickness of plastic bottles is critical to ensuring their structural integrity, product protection, material optimization, and overall quality.Plastic pipe: Both in-line and off-line measurement of plastic pipe wall thickness can be performed to ensure concentricity. Plastic tubing: Small tubing with diameters as small as 2 mm or 0.080 .

Ensuring the precise thickness of bottle walls is not just a quality control measure; it's a strategic move that can save costs, enhance product quality, and strengthen brand reputation. Pacorr's Bottle Wall Thickness . When designing or manufacturing plastic parts, wall thickness is a crucial factor that affects the performance, strength, and durability of the product. There is no single, .PosiTector UTG Ultrasonic Wall Thickness Gauges measure the remaining wall thickness of materials such as steel, plastic and more using ultrasonic technology. Ideal for measuring the effects of corrosion or erosion on tanks, pipes, or any . To ensure the best strength of the wall and even distribution of materials during the manufacturing process, the manufacturers need to measure the thickness of the walls of the .

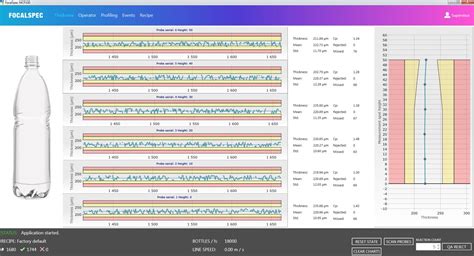

wall thickness of plastic bottles

The operator programs the desired wall-thickness control limits into the free-standing operator interface. The flat-panel monitor displays a graphical rendering of the bottle, showing the positions of the sensors taking the measurement. Thickness measurements that are within the preset upper and lower control limits are shown in green.The 72DL PLUS™ advanced ultrasonic thickness gauge delivers precision thickness measurements at high speed in a portable, easy-to-use device. Compatible with single element transducers up to 125 MHz, this innovative . For example, 0.84 measured from one pipe’s end to another is categorized as a one-inch pipe. PVC Pipes vary in size and are classified into three types – schedule 40, schedule 80, and schedule 120.

wall thickness design principles

Measuring the wall thickness of plastic bottles is critical to ensuring their structural integrity, product protection, material optimization, and overall quality. Through accurate measurement techniques and instruments from reliable suppliers like Pacorr, brands can easily adhere to industry standards and save valuable time and money.Wall thickness measurement of blown film production Film thickness measurement in the plastics industry. Our dedicated interferometric sensors of the CHRocodile 2 IT series and the CHRocodile 2 K measure the thickness and topography of various types of plastic films, containers and PET bottles. Such application flexibility is convenient, especially during film .

7. The wall thickness value is selected according to the injection molding process conditions for different raw materials. It can be selected with reference to the value range in table 7-1 below. Table 7-1. Product structure design. Maintaining a uniform plastic wall thickness is critical in injection molded part designs. In order to estimate the measurement uncertainty of the ultrasonic wall thickness measurement for the selected ultrasonic measurement system, a device with a wide range of adjustable parameters was used. Preliminary research showed significant influence of different types of probes [33]. Two parameters of the ultrasonic probes are identified as .

Four-axis laser micrometers measure the outside diameter of a part from four directions. This measurement is achieved with either four single-axis micrometers mounted to a common surface for coplanar measurement or using two dual-axis laser micrometers offset and rotated 45 degrees relative to each other. Note that with two dual-axis micrometers, the measurements .Product infomation MiniTest FH: Making wall thickness measurement more convenient. An intelligent SIDSP sensor enables the MiniTest FH to provide high-precision measurement and reproducibility while compensating for the influence of temperatures in the measuring environment and in the object being measured. A wide range of sensors allows to adapt to .Learn about the ultrasonic gauging equipment and procedures used to take small-diameter tubing measurements. Measuring Wall Thickness for Small Metal and Plastic Tubing . The examples below show typical measurements of small metal and plastic tubing with a 39DL PLUS gauge. Steel tubing: 1.5 mm (0.060 in.) diameter, 0.15 mm (0.006 in.) wall .

WARP 100 is an inline pipe measuring system for wall thickness and diameter measurement at up to 38 measuring points and 19 axes. More than 1100 measurements per second guarantee a gapless measurement. . The WARP GAUGE sensor enables the automated and continuous measurement of plastic hollow bodies from a wall thickness of 2 mm. With the non .The single most important application for ultrasonic gauging is measuring the remaining wall thickness of metal pipes, tanks, structural parts, and pressure vessels that are subject to internal corrosion that can't be seen from the outside. . Typical examples include plastic, rubber, and glass coatings on steel or other metals, and polymer .The PosiTector UTG P precision wall thickness gage is ideal for quickly and accurately measuring plastic bottle wall thickness. Application Notes. Cargo Truck Tank Wall Inspection: Thickness Measurement. DeFelsko’s PosiTector UTG Ultrasonic Wall Thickness gage non-destructively measures the thickness of cargo truck tank shells and heads.

This kind of wall thickness measurement method is now a more widely used wall thickness measurement method. The principle is: put the measuring support rod into the bottle, use its dart head to touch the measuring part, and place the measuring meter head of the capacity grid sensor on the corresponding part of the plastic bottle body to contact . thickness measurement of sliced sample. Of course, the above test plastic bottle body wall thickness way also includes infrared method, ultrasonic method and so on. The above three methods are the test principle .Measuring range: 0.5 mm - 635 mmMin./Max. mode that captures the minimum or maximum thickness at 20 measurements per second. The 27MG is designed for inspectors and maintenance engineers that need to monitor the wall .

tilted water bottle test

The thickness measurement of a wall of plastic tub- ing, in millimeters, varies according to a cumulative distribu- tion function F(x) = 200x - 401 x < 2.0050 2.0050 < x < 2.0100 x > 2.0100 Determine the following.

An ultrasonic thickness gauge is a device used to accurately measure the thickness of a given material, typically steel, plastic, alloys, and the like. UT thickness gauges are deployed in many industries but are most commonly used in Automotive, Aerospace, and Manufacturing to help ensure material thickness complies with production standards .Wall Thickness Measurement . Lior PICK 1, Ron PINCU 1, Rachel LIEBERMAN 1 . 1 Vidisco Ltd.; Or-Yehuda, Israel . Phone: +972 3 5333001, Fax: +972 3 5333002; e-mail: [email protected] . Abstract . Frequent NDT inspection in pipes seeks to if the pipe wall thickness has been altered (eroded/corroded) assessThe Olympus 72DL PLUS ultrasonic thickness gage delivers precise thickness measurements of ultra-thin materials, including automotive paint layers, plastics, metals, internal oxide, and multilayer coatings. Get reliable results at high speed with this portable, easy-to-use instrument.

Pipe Wall Thickness Measuring Device is mainly designed to measure the wall thickness of plastic pipes. The wall thickness gauge enables the measuring of the wall thickness of all types of plastic pipes with high accuracy. The measuring is conducted with a high-precision gauge mounted on the upper arm of the retainer.

The scanning box of this plastic pipe wall thickness measurement system has an ultrasonic probe inside that is used to send ultrasonic wave signal to the surface of the tubular products. Advantages 1. The device with real-time warning function can make workers quickly adjust the production line and avoid producing unqualified pipes, thus .Wall thickness measurement is a critical practice that enables industries to assess the thickness of walls and surfaces in various equipment and structures. By employing advanced measurement techniques, companies can proactively detect thinning or corrosion, ensuring the integrity and safety of critical assets.

For thickness measurements on hot plastics at temperatures higher than 50 °C or 120 °F, use a high-temperature delay line transducer. Measuring the thickness of thin plastic bottles or multilayer plastic requires a much higher frequency than is available on standard ultrasonic thickness gauges.

Accurate thickness measurement is an important testing criterion. It is now possible to calculate the thickness of PET bottles in 3 easy steps through a Non-destructive test method on Wall thickness Gauge - Magna Mike 8600.Wall thickness research from a major injection molding company with 12 years of experience, understand the algorithm and design principles.

Plastic thickness measurement is an essential process in the plastic industry. It ensures product quality, complies with regulations, and optimizes production processes. By using the methods and instruments discussed in this article, manufacturers can measure the thickness of plastic films and sheets accurately and efficiently. .

wall thickness design

WEBAbout this game. Pipa Combate - Kite Fly Game is a real kite flying game of 2020 on play store. The objective is to fly a kite and cut the opponent kites in a real kite battle. Play Kite flying game in multiplayer mode. You can play 1vs1 kite battle in online mode. Invite all your FACEBOOK friends and family and show them your kite flying skill.

plastic wall thickness measurement|wall thickness chart